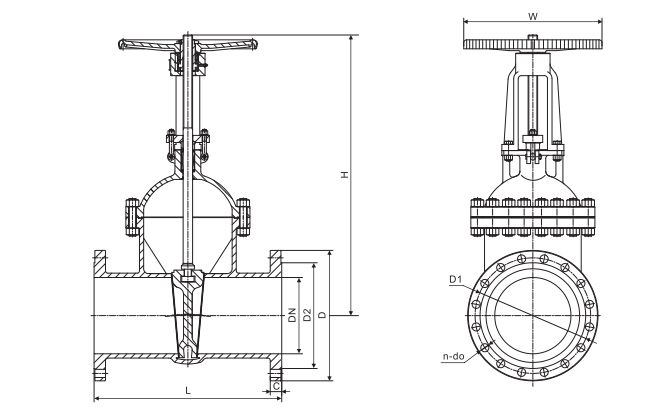

Rising Stem Gate Valve

Rising stem gate valves can be used in various applications, including water conveyance systems, seawater pipeline systems, gas pipeline systems, and weak acid-base transport systems.

Basic Information

- Size Range

- DN15-DN1200

- Temperature Range T

- 0-100℃

- Maximum Allowable Operating Pressure PN

- 1.0-2.5Mpa

- Pressure Rating

- 1.5-3.75Mpa (Shell)

1.1-2.75Mpa (Seal)

- Applicable Media

- Freshwater, seawater, air, weak acid-base, and so on.

Industrial Valve Manufacturer Since 2008

Industrial Valve Manufacturer Since 2008